Can we study an interface?

Whether you work in a textile industry, a manufacturing industry or a biomedical industry, to improve your product you will first have to understand how it is made. A good basic chemical-morphological characterisation is essential to start any process!

The outermost part of a material, its surface, is an extremely sensitive part which bears the surface characteristics such as chemical activity, adhesion, wetness, electrical properties, optical properties, corrosion-resistance, friction, and biocompatibility of the material. It is also prone to lose such

characteristics because of degradation and contamination of the environment, adhesion of process residues, etc.

Surface analysis is used not only for the development of new surfaces with high functionality and products utilising them, but also to help materials with high functions to properly exhibit their functionality.

But how can we study a surface?

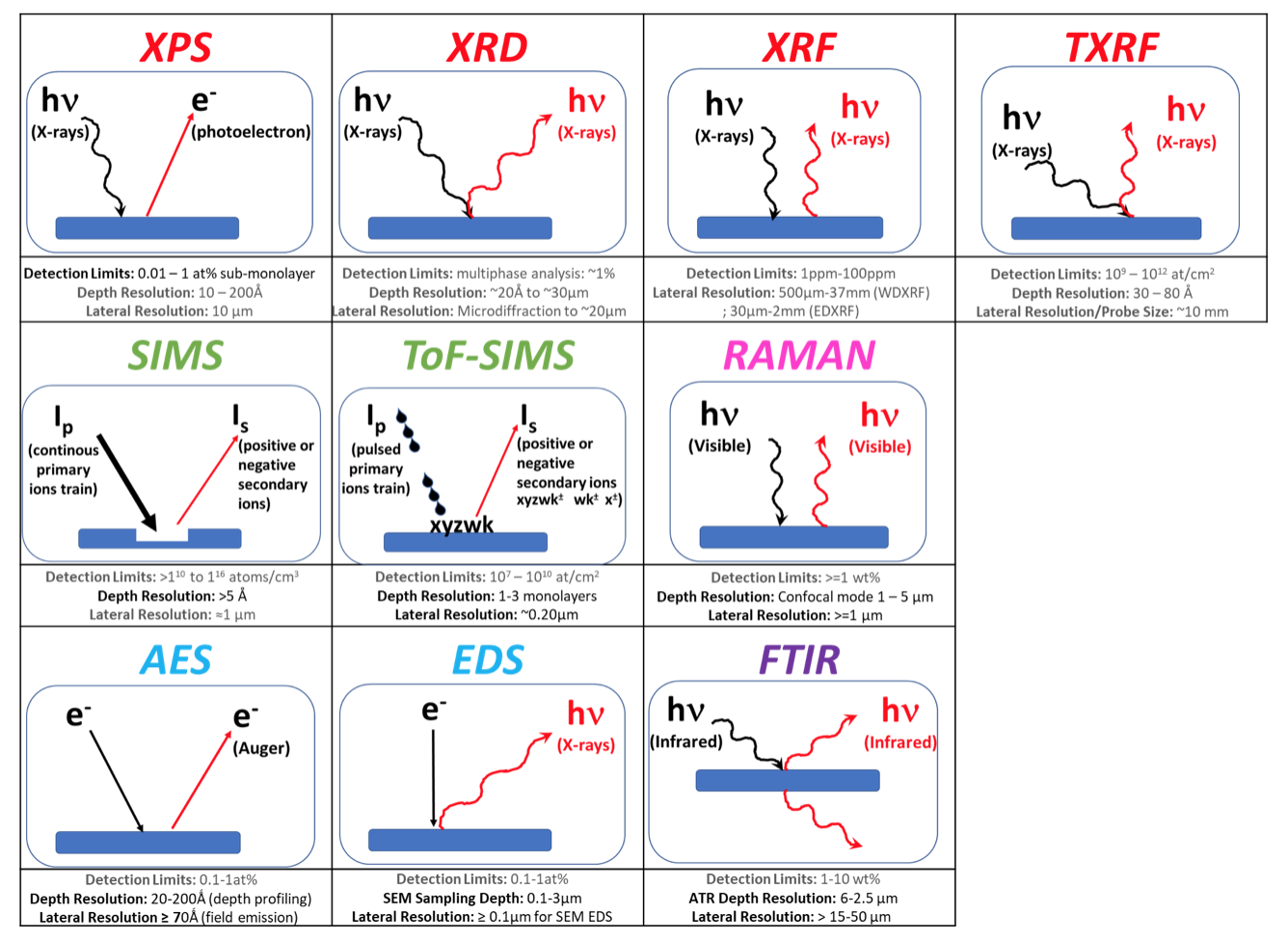

To examine a solid surface, the surface must first be stimulated: light, x-rays, and electrons are used for surface stimulation. Among the various signals that appear as a result of such surface stimulation, particles such as electrons and ions that are only given off by the surface are observed, and their properties are analysed to reveal the chemical structure of the surface.

Depending on the surface that you have and on the information that you want to have, many techniques can be applied. Here we report a scheme of the surface analysis techniques commonly used.

Indivenire can help and guide you in choosing the most suitable tools for characterize your surface!

In the next posts we will describe the different techniques.